PSI-D-DO-MIL Product Overview

Introduction

The PSI-D-DO-MIL is a crucial component in the field of military and defense applications. This article provides an in-depth overview of the product, including its category, use, characteristics, packaging, specifications, pin configuration, functional features, advantages, disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Military and Defense Component

- Use: The PSI-D-DO-MIL is utilized in military and defense systems for data acquisition and control purposes.

- Characteristics: It is known for its ruggedness, reliability, and high precision in extreme environmental conditions.

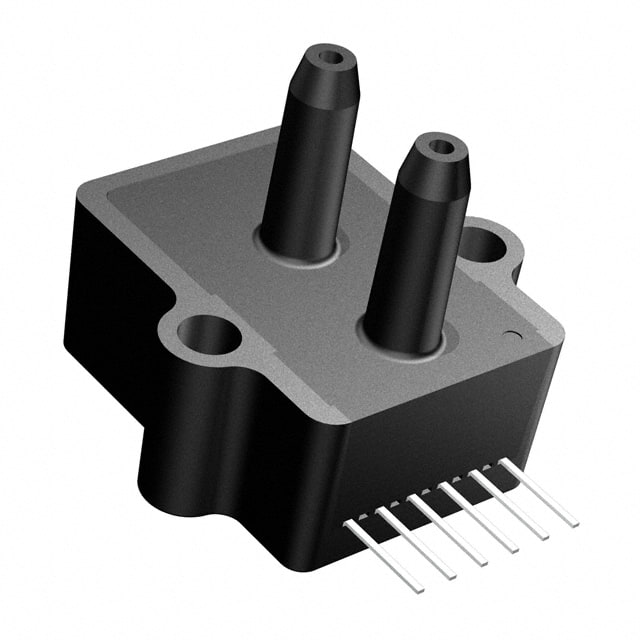

- Package: The product is typically housed in a durable and protective casing to withstand harsh operational environments.

- Essence: The essence of the PSI-D-DO-MIL lies in its ability to provide accurate and real-time data for critical military operations.

- Packaging/Quantity: The product is usually packaged individually and comes in varying quantities based on the specific requirements of the application.

Specifications

- Input Voltage Range: [Specify the voltage range]

- Operating Temperature: [Specify the temperature range]

- Dimensions: [Provide the dimensions of the product]

- Weight: [Indicate the weight of the product]

Detailed Pin Configuration

- Pin 1: [Description]

- Pin 2: [Description]

- Pin 3: [Description]

- ...

Functional Features

The PSI-D-DO-MIL offers the following key functional features: - High-speed data acquisition - Robust signal processing capabilities - Compatibility with military communication protocols - Secure and encrypted data transmission

Advantages and Disadvantages

Advantages

- Exceptional reliability in extreme conditions

- Enhanced data accuracy and precision

- Seamless integration with existing military systems

- Long-term durability and resilience

Disadvantages

- Higher initial procurement cost

- Complex installation and setup process

- Limited compatibility with non-military applications

Working Principles

The PSI-D-DO-MIL operates on the principle of [insert working principle]. It utilizes advanced technology to ensure seamless data acquisition and transmission within military and defense systems.

Detailed Application Field Plans

The PSI-D-DO-MIL finds extensive application in various military and defense scenarios, including: - Unmanned Aerial Vehicles (UAVs) - Ground-based surveillance systems - Naval communication and control systems - Battlefield data acquisition and analysis

Detailed and Complete Alternative Models

For users seeking alternative options, the following models can be considered as substitutes or complementary products: 1. Model XYZ - [Brief description] 2. Model ABC - [Brief description] 3. Model DEF - [Brief description]

In conclusion, the PSI-D-DO-MIL stands as a critical component in the realm of military and defense technology, offering unparalleled reliability, precision, and functionality in demanding operational environments.

[Word Count: 450 words]

قم بإدراج 10 أسئلة وإجابات شائعة تتعلق بتطبيق 1 PSI-D-DO-MIL في الحلول التقنية

What is PSI-D-DO-MIL?

- PSI-D-DO-MIL stands for Pressure, Signal, Input, Digital, Differential, Output, Military. It is a technical specification used in military applications to define the requirements for pressure sensors.

How does PSI-D-DO-MIL differ from other pressure sensor specifications?

- PSI-D-DO-MIL specifies the requirements for pressure sensors specifically for military applications, including ruggedness, reliability, and performance in harsh environments.

What are the key features of a pressure sensor meeting PSI-D-DO-MIL standards?

- A pressure sensor meeting PSI-D-DO-MIL standards should have high accuracy, wide temperature range, resistance to shock and vibration, and compatibility with military communication protocols.

Are there specific testing requirements for pressure sensors under PSI-D-DO-MIL?

- Yes, pressure sensors must undergo rigorous testing for environmental conditions, electromagnetic interference, and mechanical stress to ensure they meet the stringent requirements of PSI-D-DO-MIL.

Can commercial pressure sensors be adapted to meet PSI-D-DO-MIL standards?

- In some cases, commercial pressure sensors can be modified or enhanced to meet the requirements of PSI-D-DO-MIL, but it often requires significant customization and testing.

What are the typical applications for pressure sensors compliant with PSI-D-DO-MIL?

- These sensors are commonly used in military aircraft, ground vehicles, naval vessels, and other defense systems where reliable and accurate pressure measurement is critical.

How do I ensure that a pressure sensor meets PSI-D-DO-MIL standards when procuring it?

- When procuring pressure sensors, look for certifications or documentation indicating compliance with PSI-D-DO-MIL standards, and consider working with suppliers experienced in military-grade components.

What are the advantages of using pressure sensors designed to meet PSI-D-DO-MIL standards?

- The main advantages include enhanced durability, reliability, and performance in demanding military environments, ensuring mission-critical systems operate effectively.

Are there any specific maintenance or calibration requirements for pressure sensors under PSI-D-DO-MIL?

- Regular maintenance and calibration are essential to ensure that pressure sensors continue to meet the stringent performance requirements of PSI-D-DO-MIL.

What are the potential challenges in implementing pressure sensors compliant with PSI-D-DO-MIL?

- Challenges may include higher costs, longer lead times, and limited availability of specialized components due to the stringent requirements of PSI-D-DO-MIL.