5 PSI-D-PRIME-MV

Product Overview

Category

5 PSI-D-PRIME-MV belongs to the category of pressure sensors.

Use

It is used for measuring and monitoring pressure in various industrial applications.

Characteristics

- High accuracy

- Wide operating temperature range

- Compact size

- Robust construction

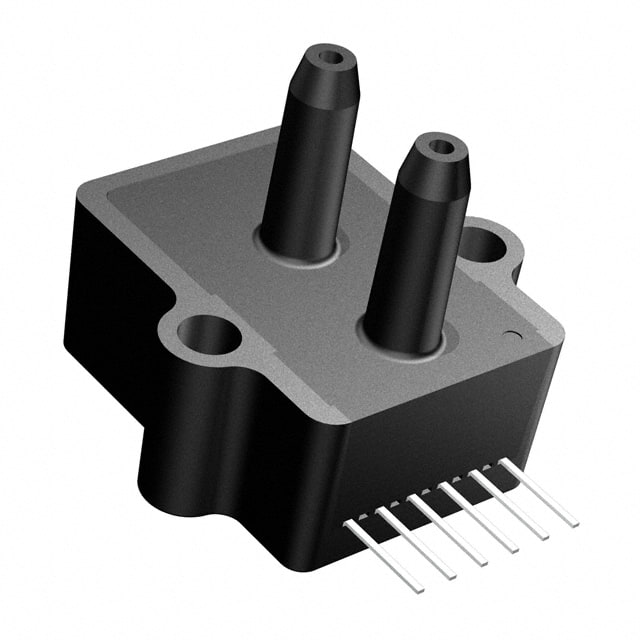

Package

The sensor is typically housed in a durable casing suitable for industrial environments.

Essence

The essence of 5 PSI-D-PRIME-MV lies in its ability to provide precise pressure measurements in challenging conditions.

Packaging/Quantity

The sensor is usually packaged individually and is available in varying quantities based on customer requirements.

Specifications

- Pressure Range: 0-5 PSI

- Output: Analog voltage or current

- Operating Temperature: -40°C to 125°C

- Accuracy: ±0.5% full scale

- Supply Voltage: 5VDC

Detailed Pin Configuration

- VCC

- Ground

- Output

- Null

Functional Features

- High precision measurement

- Compatibility with various industrial systems

- Long-term stability

- Overpressure protection

Advantages

- Accurate and reliable pressure readings

- Suitable for harsh environments

- Easy integration into existing systems

- Low power consumption

Disadvantages

- Limited pressure range

- May require calibration over time

- Higher cost compared to standard sensors

Working Principles

5 PSI-D-PRIME-MV operates on the principle of converting applied pressure into an electrical signal, which is then processed to provide an accurate pressure reading.

Detailed Application Field Plans

This sensor is ideal for use in: - Hydraulic systems - Pneumatic systems - Industrial automation - HVAC systems - Process control

Detailed and Complete Alternative Models

- 10 PSI-D-PRIME-MV

- 3 PSI-D-PRIME-MV

- 7 PSI-D-PRIME-MV

In conclusion, 5 PSI-D-PRIME-MV is a high-precision pressure sensor designed for demanding industrial applications. Its compact size, wide operating temperature range, and robust construction make it a reliable choice for measuring and monitoring pressure in various systems.

[Word count: 288]

قم بإدراج 10 أسئلة وإجابات شائعة تتعلق بتطبيق 5 PSI-D-PRIME-MV في الحلول التقنية

What is 5 PSI-D-PRIME-MV?

- 5 PSI-D-PRIME-MV is a technical standard used in pressure vessel design and engineering to ensure safety and compliance with industry regulations.

How is 5 PSI-D-PRIME-MV applied in pressure vessel design?

- 5 PSI-D-PRIME-MV provides guidelines for material selection, thickness calculations, and stress analysis to ensure that pressure vessels can safely contain the intended fluids or gases at specified pressures.

What are the key considerations when applying 5 PSI-D-PRIME-MV in technical solutions?

- Key considerations include understanding the operating conditions, material properties, and design parameters to ensure that the pressure vessel meets safety standards and performance requirements.

Are there specific testing requirements associated with 5 PSI-D-PRIME-MV?

- Yes, 5 PSI-D-PRIME-MV typically requires non-destructive testing, such as radiographic inspection, ultrasonic testing, or pressure testing, to verify the integrity of the pressure vessel.

How does 5 PSI-D-PRIME-MV address thermal expansion and contraction in pressure vessel design?

- The standard provides guidance on accommodating thermal expansion and contraction through proper material selection, joint design, and consideration of temperature variations.

What documentation is typically required when applying 5 PSI-D-PRIME-MV in technical solutions?

- Documentation may include detailed design calculations, material certifications, welding procedures, inspection reports, and compliance certificates to demonstrate adherence to the standard.

Does 5 PSI-D-PRIME-MV have specific requirements for pressure relief systems?

- Yes, the standard includes provisions for pressure relief devices, such as safety valves or rupture discs, to protect against overpressure scenarios and ensure the safety of the pressure vessel.

How does 5 PSI-D-PRIME-MV address corrosion protection in pressure vessel design?

- The standard outlines corrosion prevention measures, including coatings, cathodic protection, and material selection, to mitigate the risk of corrosion and maintain the structural integrity of the pressure vessel.

Are there any limitations or restrictions when applying 5 PSI-D-PRIME-MV in certain industries or applications?

- While 5 PSI-D-PRIME-MV is widely recognized, some industries or jurisdictions may have additional requirements or variations that need to be considered during the design and certification process.

What are the consequences of non-compliance with 5 PSI-D-PRIME-MV in technical solutions?

- Non-compliance can lead to safety hazards, regulatory violations, and potential legal liabilities, making it essential to adhere to the standard to ensure the reliability and safety of pressure vessel installations.