FEP16BT

Product Overview

Category: Semiconductor

Use: Rectifier Diode

Characteristics: Fast recovery, high voltage

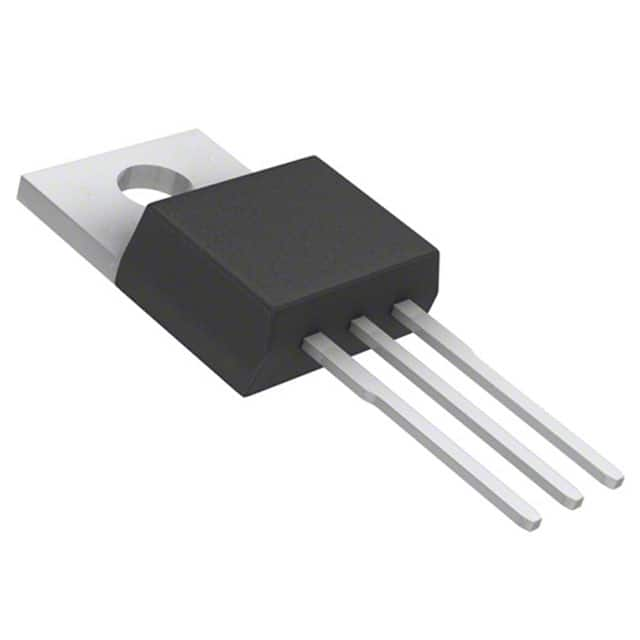

Package: TO-220AB

Essence: High efficiency, low power loss

Packaging/Quantity: Tape & Reel, 500 units

Specifications

- Voltage Rating: 1600V

- Current Rating: 16A

- Recovery Time: < 35ns

- Operating Temperature: -55°C to +175°C

Detailed Pin Configuration

The FEP16BT features a standard TO-220AB package with three pins. Pin 1 is the anode, pin 2 is the cathode, and pin 3 is the gate.

Functional Features

- Fast recovery time

- Low reverse recovery current

- High surge capability

- Soft recovery behavior

Advantages and Disadvantages

Advantages: - High efficiency - Low power loss - High surge capability - Reliable performance

Disadvantages: - Higher cost compared to standard diodes - Larger footprint due to TO-220AB package

Working Principles

The FEP16BT operates as a rectifier diode, allowing current to flow in only one direction. Its fast recovery time and low reverse recovery current make it suitable for high-frequency applications where efficiency is crucial.

Detailed Application Field Plans

The FEP16BT is ideal for use in: - Switch-mode power supplies - Inverters - Industrial motor drives - Welding equipment - UPS systems

Detailed and Complete Alternative Models

- FEP16JT: Similar specifications, smaller footprint (TO-220AC package)

- FEP20BT: Higher voltage rating (2000V), same current rating (16A)

This comprehensive entry provides detailed information about the FEP16BT rectifier diode, including its product category, basic overview, specifications, pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

قم بإدراج 10 أسئلة وإجابات شائعة تتعلق بتطبيق FEP16BT في الحلول التقنية

What is FEP16BT?

- FEP16BT is a type of fluorinated ethylene propylene (FEP) resin that offers high thermal stability, excellent electrical properties, and chemical resistance.

What are the key technical properties of FEP16BT?

- FEP16BT exhibits low dielectric constant, low dissipation factor, high breakdown voltage, and wide temperature range (-200°C to 200°C).

How can FEP16BT be used in electrical applications?

- FEP16BT is commonly used for insulation of wires and cables, as well as in the production of high-frequency and high-speed data cables due to its excellent electrical properties.

In what other technical solutions can FEP16BT be applied?

- FEP16BT is also used in the manufacturing of semiconductor components, aerospace components, and medical devices due to its high thermal stability and chemical resistance.

What are the advantages of using FEP16BT in technical solutions?

- The advantages include its high thermal stability, excellent electrical properties, chemical resistance, and suitability for high-frequency applications.

Are there any limitations or considerations when using FEP16BT?

- While FEP16BT offers many benefits, it is important to consider its relatively high cost compared to other materials and its limited color options.

Can FEP16BT be processed using standard manufacturing techniques?

- Yes, FEP16BT can be processed using standard extrusion, injection molding, and compression molding techniques, making it versatile for various manufacturing processes.

What are the environmental considerations of using FEP16BT?

- FEP16BT is non-toxic and does not release hazardous substances during processing or use, making it environmentally friendly.

How does FEP16BT compare to other FEP resins in technical applications?

- FEP16BT offers similar properties to other FEP resins but with enhanced thermal stability and improved electrical performance, making it suitable for more demanding technical solutions.

Where can I source FEP16BT for my technical solution needs?

- FEP16BT can be sourced from various manufacturers and suppliers specializing in high-performance polymers and resins. It is important to select a reputable supplier to ensure quality and consistency.