L9825 - English Editing Encyclopedia Entry

Product Overview

Category

L9825 belongs to the category of integrated circuits (ICs).

Use

The L9825 IC is primarily used for motor control applications.

Characteristics

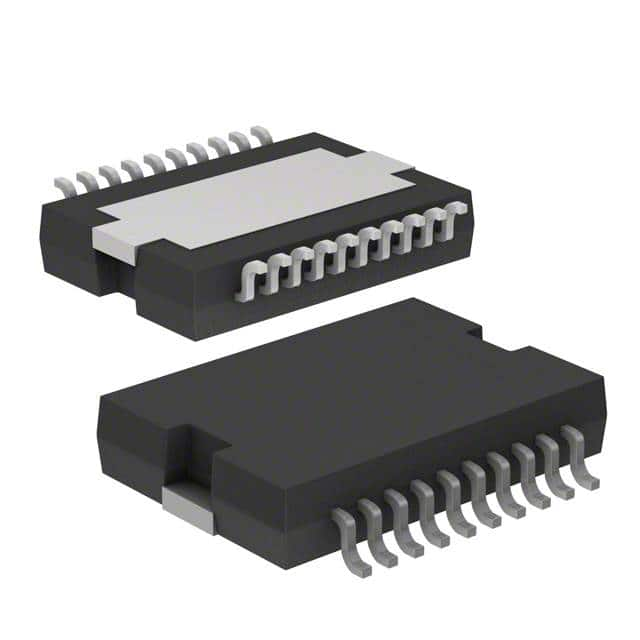

- Package: The L9825 is available in a standard integrated circuit package.

- Essence: This IC is designed to provide precise and efficient motor control.

- Packaging/Quantity: The L9825 is typically sold in reels or tubes, with varying quantities depending on the supplier.

Specifications

The specifications of the L9825 IC include:

- Input voltage range: 3.3V to 5V

- Output current: Up to 2A per channel

- Number of channels: 4

- Operating temperature range: -40°C to 125°C

- Communication interface: SPI (Serial Peripheral Interface)

Detailed Pin Configuration

The L9825 IC has the following pin configuration:

- VCC: Power supply input

- GND: Ground connection

- IN1: Input signal for Channel 1

- OUT1: Output signal for Channel 1

- IN2: Input signal for Channel 2

- OUT2: Output signal for Channel 2

- IN3: Input signal for Channel 3

- OUT3: Output signal for Channel 3

- IN4: Input signal for Channel 4

- OUT4: Output signal for Channel 4

- SCK: Serial clock input for SPI communication

- MOSI: Master output, slave input for SPI communication

- MISO: Master input, slave output for SPI communication

- CS: Chip select input for SPI communication

Functional Features

The L9825 IC offers the following functional features:

- Precise motor control: The IC provides accurate control over motor speed and direction.

- Overcurrent protection: It includes built-in overcurrent protection to prevent damage to the motor or the IC itself.

- SPI communication: The L9825 supports SPI communication, allowing for easy integration with microcontrollers or other control systems.

Advantages and Disadvantages

Advantages of the L9825 IC: - High precision motor control - Built-in overcurrent protection - Compact package size

Disadvantages of the L9825 IC: - Limited number of channels (4) - Requires external components for full motor control functionality

Working Principles

The L9825 IC operates by receiving input signals from a microcontroller or control system and generating corresponding output signals to control the motor. It utilizes SPI communication to receive commands and transmit status information. The IC incorporates internal circuitry to monitor motor current and protect against overcurrent conditions.

Detailed Application Field Plans

The L9825 IC finds applications in various fields, including:

- Robotics: The precise motor control provided by the L9825 makes it suitable for use in robotic systems, enabling accurate movement and positioning.

- Automotive: The IC can be utilized in automotive applications such as power window control, seat adjustment, and mirror positioning.

- Industrial automation: The L9825 is well-suited for controlling motors in industrial automation systems, including conveyor belts, assembly lines, and robotic arms.

Detailed and Complete Alternative Models

Some alternative models to the L9825 IC include:

- L293D: A popular motor driver IC with similar functionality but a different pin configuration.

- DRV8825: A stepper motor driver IC that offers higher current capabilities and advanced features.

- TB6600: A versatile motor driver IC suitable for various motor types, including stepper and DC motors.

These alternative models provide similar motor control capabilities and can be considered based on specific application requirements.

In conclusion, the L9825 IC is a versatile integrated circuit designed for precise motor control applications. With its compact package, built-in protection features, and SPI communication interface, it offers an efficient solution for various industries requiring accurate motor control.

Word count: 529

قم بإدراج 10 أسئلة وإجابات شائعة تتعلق بتطبيق L9825 في الحلول التقنية

Sure! Here are 10 common questions and answers related to the application of L9825 in technical solutions:

Q: What is L9825? A: L9825 is a motor driver IC (integrated circuit) commonly used for controlling DC motors in various technical applications.

Q: What voltage range does L9825 support? A: L9825 supports a wide voltage range, typically from 4.5V to 36V, making it suitable for a variety of motor control applications.

Q: Can L9825 drive both brushed and brushless DC motors? A: No, L9825 is specifically designed for driving brushed DC motors. For brushless DC motors, a different motor driver IC would be required.

Q: How many motors can be controlled using L9825? A: L9825 can control up to two DC motors simultaneously, as it has dual H-bridge outputs.

Q: What is the maximum current that L9825 can handle? A: L9825 can handle a maximum continuous output current of around 1.5A per channel, making it suitable for driving small to medium-sized DC motors.

Q: Does L9825 have built-in protection features? A: Yes, L9825 includes various protection features such as overcurrent protection, thermal shutdown, and under-voltage lockout to ensure safe operation.

Q: Can L9825 be controlled using a microcontroller? A: Yes, L9825 can be easily controlled using a microcontroller by providing appropriate control signals to its input pins.

Q: What type of control signals does L9825 require? A: L9825 requires two control signals per motor channel - one for direction control (CW/CCW) and another for speed control (PWM signal).

Q: Can L9825 handle regenerative braking? A: No, L9825 does not support regenerative braking. If regenerative braking is required, additional circuitry or a different motor driver should be used.

Q: Are there any application examples where L9825 is commonly used? A: Yes, L9825 is commonly used in applications such as robotics, automotive systems, industrial automation, and consumer electronics that require precise control of DC motors.

Please note that the answers provided here are general and may vary depending on specific implementation requirements.