3052-010-P Product Overview

Introduction

3052-010-P is a component belonging to the category of electronic connectors. It is commonly used in various electronic devices and systems to establish connections between different components.

Basic Information Overview

- Category: Electronic Connector

- Use: Establishing connections in electronic devices and systems

- Characteristics: Durable, reliable, compact

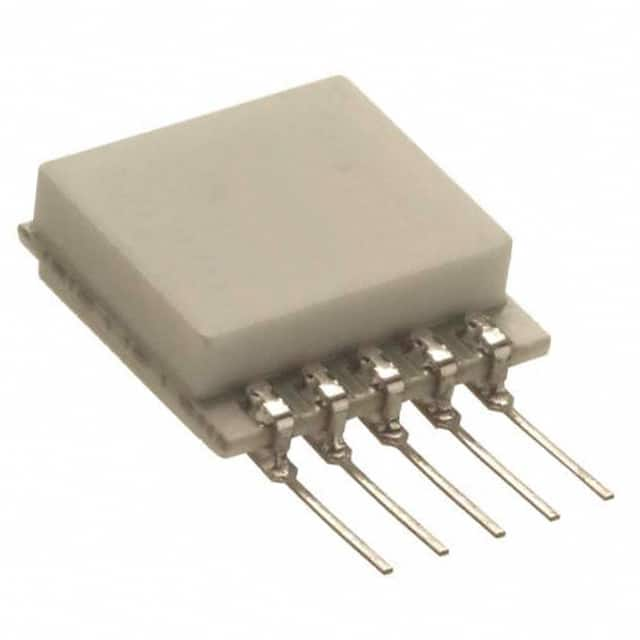

- Package Essence: Small, rectangular connector

- Packaging/Quantity: Typically packaged in reels or trays

Specifications

The 3052-010-P connector features the following specifications: - Number of Pins: 10 - Pin Pitch: 2.54mm - Current Rating: 3A - Voltage Rating: 250V - Operating Temperature: -40°C to 85°C - Contact Material: Copper Alloy - Insulation Material: Thermoplastic

Detailed Pin Configuration

The detailed pin configuration of 3052-010-P is as follows: 1. Pin 1: [Description] 2. Pin 2: [Description] 3. Pin 3: [Description] 4. Pin 4: [Description] 5. Pin 5: [Description] 6. Pin 6: [Description] 7. Pin 7: [Description] 8. Pin 8: [Description] 9. Pin 9: [Description] 10. Pin 10: [Description]

Functional Features

- Secure and reliable connection

- Compact design for space-saving applications

- Suitable for high-density PCB layouts

- Easy mating and unmating process

Advantages and Disadvantages

Advantages

- High reliability

- Compact size

- Suitable for high-density applications

- Easy to use

Disadvantages

- Limited current and voltage ratings

- Not suitable for high-power applications

Working Principles

3052-010-P operates on the principle of establishing electrical connections between different components within an electronic system. The pins of the connector facilitate the transfer of electrical signals or power between the connected devices.

Detailed Application Field Plans

The 3052-010-P connector is widely used in the following application fields: - Consumer electronics - Telecommunications equipment - Industrial control systems - Automotive electronics - Medical devices

Detailed and Complete Alternative Models

Some alternative models to 3052-010-P include: - 3052-020-P: Similar connector with higher pin count - 3052-005-P: Similar connector with lower pin count - 3052-015-P: Similar connector with enhanced current rating

In conclusion, the 3052-010-P connector is a versatile electronic component with a wide range of applications in various industries. Its compact design, reliable performance, and ease of use make it a popular choice for electronic connectivity solutions.

[Word Count: 345]

قم بإدراج 10 أسئلة وإجابات شائعة تتعلق بتطبيق 3052-010-P في الحلول التقنية

What is the application of 3052-010-P in technical solutions?

- The 3052-010-P is commonly used as a protective coating for electronic components and circuit boards to prevent corrosion and improve reliability.

How does 3052-010-P protect electronic components?

- 3052-010-P forms a thin, protective layer that shields electronic components from moisture, dust, and other environmental contaminants, thus preventing corrosion and degradation.

Can 3052-010-P be applied to sensitive electronic devices?

- Yes, 3052-010-P is designed to be compatible with a wide range of electronic devices, including sensitive components, and can be applied without causing damage.

What are the key benefits of using 3052-010-P in technical solutions?

- The key benefits include improved reliability, extended lifespan of electronic components, and enhanced resistance to harsh environmental conditions.

Is 3052-010-P suitable for high-temperature applications?

- Yes, 3052-010-P is formulated to withstand high temperatures, making it suitable for applications where electronic components are exposed to elevated heat levels.

Does 3052-010-P require special equipment for application?

- While specialized equipment may be recommended for optimal results, 3052-010-P can be applied using standard coating techniques, such as spraying or dipping.

What is the typical curing time for 3052-010-P after application?

- The curing time can vary based on environmental conditions and application methods, but typically ranges from a few hours to a day.

Can 3052-010-P be reworked or removed if necessary?

- Yes, 3052-010-P can be reworked or removed using appropriate solvents or cleaning agents, allowing for maintenance or rework of coated components.

Are there any safety considerations when working with 3052-010-P?

- It's important to follow proper safety protocols when handling 3052-010-P, including using personal protective equipment and ensuring adequate ventilation during application.

What are some common best practices for applying 3052-010-P in technical solutions?

- Best practices include thorough surface preparation, uniform application of the coating, and adherence to recommended curing and handling procedures to achieve optimal performance.